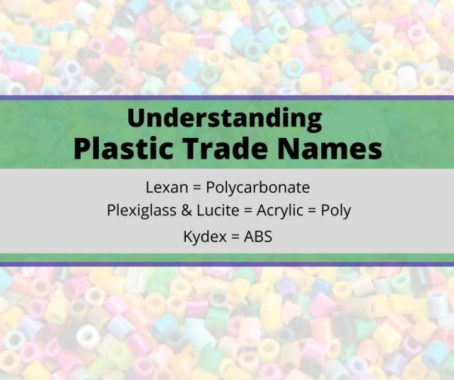

Understanding the difference between a brand and material is a huge part of material selection when it comes to plastic.

Lots of products in our everyday life are recognized by a brand name rather than the product itself i.e. kleenex, ziploc, bubble wrap, crock-pot, etc.

Plastic is no different.

There are plenty of resources out there for interpreting the hundreds, if not thousands of different plastic trade names. I wanted to put together a concise, comprehensive explanation of the top 3 plastic categories and their most common trade names.

Lexan wasn’t the first trade name for polycarbonate, and even today there are several others, but it is definitely the most widely recognized.

Polycarbonate is a very strong, transparent, impact resistant plastic. It’s applications are diverse, but it is often used for bullet proof “glass” and safety shields/enclosures for machinery, as well as re-usable drinking bottles. Despite it’s strength, polycarbonate is generally susceptible to scratches.

Acrylic goes by lots of different names as well.

This material is highly scratch resistant, transparent, and is typically used as a glass alternative because it has a much higher impact strength than glass. It is, however, much less impact resistant than polycarbonate. Modern acrylic sheet serves well for outdoor applications because it is inherently UV resistant, while other materials have to go through secondary processes to add UV protection.

ABS is a very common plastic that has high shock absorbency. Applications are very diverse and include household/consumer goods, protective headgear, musical instruments, and automotive trim components.

Knowing every trade name, formulation, and application is not all that important. What is important, is remaining flexible when selecting a material for your product. Demanding that your part be made from Lexan could cost you twice as much as an equivalent polycarbonate without the brand name.

At Ehren-Haus, it happens all too often that a client comes to us with a specific material on a product drawing without explaining the application of the product. We can attempt to open communication, but ultimately if a client chooses a material, we use that material. 6 months later when the product has yellowed from sun damage and is showing severe cracking from the chemicals they clean it with…that customer comes to us to fix the problem. Had we known the application before we produced it, we could have recommended a completely different material and possibly saved them some money! The moral of the story is communicate with your manufacturer on all aspects of your design prior to production. If your manufacturer isn’t interested in helping you select a material, you should select a different manufacturer.

These Acrylic, ABS and Polycarbonate Plastic materials that I’ve listed only account for a small fraction of the number of plastic options there are. Even within these categories, there are countless formulations, thicknesses, colors, etc. that could affect your material selection process. Don’t rely on marketing propaganda from a plastic company to determine the best solution, get help from someone experienced in the field.

Aside from choosing the right material, our in-house Plastic Fabrication, Vacuum Forming and CNC Machining Services with our attention to detail and commitment to quality makes the customer successful.

If you’re looking for some guidance in regards to what material is best for your product, give us a call.