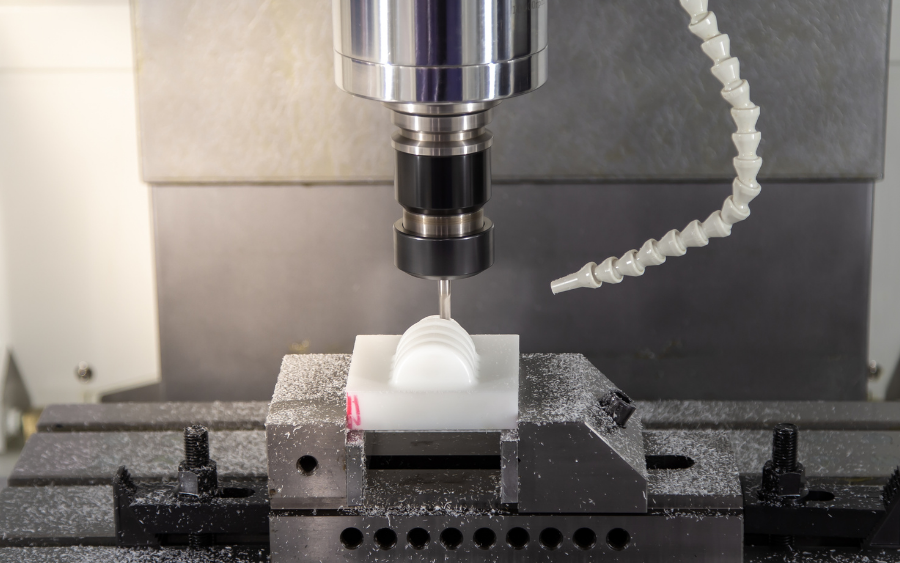

With progress in industrial automation, tools and machinery are typically controlled by pre-programmed computer software. Three-dimensional cutting tasks can be completed with a single set of instructions with CNC machining. CNC (Computer Numerical Control) machining is used in a wide variety of industries. With their enhanced accuracy and quality, the medical industry in particular can benefit from the use of CNC machines.

The rise in demand for medical supplies since the start of the pandemic coupled with the manufacturing industry's ability to supply that demand explains why the future of CNC machining appears to be so promising. Some experts expect that the CNC machine tool industry will increase by $24.91 billion by 2024 with a compound annual growth rate of nearly 9%. CNC machining is typically the only method of production capable of satisfying standards for certain types of high-precision parts in medical device equipment with complex geometries.

CNC machining is a critical manufacturing method in the medical industry because of its precision, speed, and material diversity. Machined parts can be found in all aspects of healthcare, from surgical equipment to bedside monitoring systems to hip implants. Demand for ventilators, personal protective equipment (PPE), and other medical equipment has surged as a result of the epidemic. Due to the rapid rise in demand, as well as reduced production capacity and interrupted supply chains, many regions are unable to obtain life-saving medicines and equipment. Many CNC manufacturers, even those outside the medical OEMs specifically, have started producing new medical equipment components to assist supply chains. Ehren-Haus manufactures a variety of personal protective equipment (PPE) such as face shields, sneeze guards, and face mask dispensers. Medical device enclosures and other products are manufactured using a variety of materials such as: Acrylonitrile Butadiene Styrene, Polyamide, or PETG.

According to Market Research Future's current CNC machine market report, the market will be worth around $90 billion by 2026, rising at a 5% CAGR from 2021 to 2026. CNC machine market revenues remained reassuringly stable even through the COVID-19 challenges. During the COVID-19 epidemic, CNC fabrication and machining performed a critical role in keeping employees and families safe, and it will continue to do so in 2021 and beyond.

A face shield/medical visor is designed to shield the face from risks such as debris, chemical splashes, and potentially contagious materials. For full facial protection, the protective visors are practical, lightweight, and comfortable to wear for long periods. The anti-fog visors enable maximum visibility while in use.

Sneeze guards and other such products are in high demand, particularly among industries that provide critical customer service and healthcare. Because these products are required for COVID-19 prevention, demand is predicted to be high throughout 2021. Plastic face shields, intubation boxes, sneeze guards, and face masks will continue to be in high demand even when schools, medical practices, companies, and social services return to normal.

Due to the nature of how Magnetic Resonance machines work, the usage of plastics is almost critical to their operation. Also, when a patient is placed in the machine they must remain as still as possible for accurate imaging. Braces are often used to hold the patient in place as comfortably and still as possible. However, since an MRI uses magnets, plastics are often used for those braces. CNC machining enables the production of these braces to be both high quality and rigid while also comfortable for the patient.

The CNC machine industry is tremendously promising due to the constantly developing tool-making industries around the world. The CNC machine market has always been subject to technical advancements, and more automation is expected to be used to meet consumer expectations for increased efficiency. Furthermore, a shortage of qualified personnel, restrictions on working hours, and rising labor expenses, as well as increased demand for quality control and tolerances, drive manufacturing organizations throughout the world to add improved automation tools for their facilities. Ehren-Haus can provide you with CNC machining services for custom medical products, from the first item approval through a finalized, functional product.

Ehren-Haus specializes in a variety of services, including custom plastic fabrication, CNC plastic machining, cutting, routing, and assembly. We specialize in all types of plastic parts and final products, including those with complex designs, owing to our industry experience and a team of experts in plastic manufacturing methods. We also offer the industry's fastest turnaround time.